Cnc fanuc g76 threading cycle

Содержание:

- More …

- Fanuc G68 Coordinate Rotation

- Fanuc G68 Coordinate Rotation – Subprogram Example

- Selca G50 G51 Offset / rotation of the coordinate system on the plane

- Fanuc G52 Local Coordinate G15 G16 Polar Coordinate Program Example

- Selca CNC G51 Offset / Rotation of Coordinate Program Example

- Fanuc G15 G16 End / Begin Polar Coordinate Interpolation

- NCT Programming Drilling in a Circle with G81 Drilling Cycle G16 Polar Coordinate

- Hust CNC Mill G90 Absolute Coordinates G91 Incremental Coordinate Example

- Example of Fanuc G07.1 Cylindrical Interpolation Program

- Fanuc G70 G71 Rough and Finish Turning Cycle Program Example

- Selca G75 G76 Polar coordinate programming

- Fanuc CNC Program Example

- Selca G891 Angles of rotation with inclined probes

- Osai 10 Series CNC Program Example

- G81 Drilling Cycle G84 Tapping Cycle CNC Program Example

- Fanuc G21 Measuring in Millimeter with CNC Lathe Programming Example

- Socket with Thread Fanuc 21i CNC Program Exercise

- Passes

- More …

- How to Fully Control G76 Threading Cycle Number of Pass and Depth of Cut Explained

- G78 Threading Cycle – Fanuc Lathe Programming

- Mach3 Turn G76 Threading Canned Cycle

- Controlling Threading Infeed Angle with Fanuc G76 Threading Cycle

- Internal Threading on Fanuc 21i 18i 16i with G76 Threading Cycle

- CNC Fanuc G92 Threading Cycle

- G76 Threading Cycle One Line Format for Fanuc 10/11/15T

- Haas G76 Threading Cycle Multiple Pass

- Taper Threading with G92 Threading Cycle

- Fanuc G76 Thread Cycle for Dummies

- Sinumerik L97 Thread Cutting Cycle

- External Thread Cutting with G76 Threading Cycle on Fanuc 21i 18i 16i CNC

- CNC Programming Example G92 Taper Threading Cycle

- Taper Threading with G32 a CNC Programming Example

- Recommended Thread Infeed Passes Table

- Tapered Threading with Fanuc G76 Threading Cycle

- CNC Fanuc G33 G32 Threading G Code

- G76 Thread Cycle a CNC Programming Example

- Sinumerik L97 Thread Cutting Cycle Program Example for External Threading

- More …

- How to Fully Control G76 Threading Cycle Number of Pass and Depth of Cut Explained

- G76 Thread Cycle a CNC Programming Example

- CNC Fanuc G76 Threading Cycle

- CNC Fanuc G92 Threading Cycle

- G78 Threading Cycle – Fanuc Lathe Programming

- G76 Threading Cycle One Line Format for Fanuc 10/11/15T

- Mach3 Turn G76 Threading Canned Cycle

- Taper Threading with G92 Threading Cycle

- Multi Start Threads with Fanuc G76 Threading Cycle

- Controlling Threading Infeed Angle with Fanuc G76 Threading Cycle

- External Thread Cutting with G76 Threading Cycle on Fanuc 21i 18i 16i CNC

- Internal Threading on Fanuc 21i 18i 16i with G76 Threading Cycle

- CNC Programming Example G92 Taper Threading Cycle

- Sinumerik L97 Thread Cutting Cycle

- Sinumerik L97 Thread Cutting Cycle Program Example for External Threading

- Haas G76 Threading Cycle Multiple Pass

- Siemens Sinumerik 840D Thread Cutting Cycle CYCLE97

- Tapered Threading with Fanuc G76 Threading Cycle

- CNC Fanuc G33 G32 Threading G Code

- Thread Start and End Positions

- Fanuc G76 Threading Cycle Explanation

- First Cut Depth

- Spring Passes

- Fanuc robodrill

- Minimum Cutting Depth

- Циклы сверления и формирования отверстий

- Thread Infeed Angle (also called Tool Nose Angle)

More …

Fanuc G68 Coordinate Rotation

ContentsG68 Coordinate RotationProgrammingParametersG91 Incremental ModeG69 Cancel Coordinate RotationProgramming G68 Coordinate Rotation Fanuc G68 Coordinate Rotation G-Code makes it easy for cnc machinist to run a pattern of operations in a…

Fanuc G68 Coordinate Rotation – Subprogram Example

CNC program example code to show how Fanuc G68 Coordinate rotation g-code can be used in a subprogram to take most benefit from it’s functionality. ContentsG68 Coordinate Rotation ExampleMain-programSubprogram G68 Coordinate…

Selca G50 G51 Offset / rotation of the coordinate system on the plane

Selca G50 G51 Offset / rotation of the coordinate system on the plane ContentsG50 Cancels the offset/rotationProgrammingG51 Offset / rotationProgrammingParameters G50 Cancels the offset/rotation G50 Cancels the offset / rotation…

Fanuc G52 Local Coordinate G15 G16 Polar Coordinate Program Example

;Fanuc Program Example ;G52 Local Coordinate System ;G15 G16 Polar Coordinate O1453 G91 G28 X0 Y0 Z0 M06 101 M03 S1000 G90 G54 G43 H1 G52 X100 Y100 G00 X0…

Selca CNC G51 Offset / Rotation of Coordinate Program Example

N1 [PROFILE 3 N2 $1M0X-105.I103.Y-63.7J69.3 N3 G17 N4 O1 N5 T1 N6 F1000S1200M3 N7 Z100R N8 X-20Y27R N9 Z2R N10 Z-10 N11 G49I2 N12 G41K2 N13 L=1 N14 G20X0Y0I-25 N15…

Fanuc G15 G16 End / Begin Polar Coordinate Interpolation

ContentsG15 End Polar Coordinate InterpolationProgrammingG16 Begin Polar Coordinate InterpolationProgrammingExample G15 End Polar Coordinate Interpolation G15 End Polar Coordinate Interpolation Programming G15 G16 Begin Polar Coordinate Interpolation G16 Begin Polar Coordinate…

NCT Programming Drilling in a Circle with G81 Drilling Cycle G16 Polar Coordinate

NCT program example to show how G81 drilling cycle can be used to drill in a circle using G15 G16 Polar Coordinate Commands and G81 Drilling Cycle. ContentsG CodesNCT Programming…

Hust CNC Mill G90 Absolute Coordinates G91 Incremental Coordinate Example

Hust CNC simple basic G-code program example, which shows the difference between G90 Absolute Coordinate & G91 Incremental Coordinate. This tutorial also applies on most Fanuc cnc controls as well….

Example of Fanuc G07.1 Cylindrical Interpolation Program

O0001 (CYLINDRICAL INTERPOLATION ); N01 G00 G90 Z100.0 C0 ; N02 G01 G91 G18 Z0 C0 ; N03 G07.1 C57299 ; N04 G90 G01 G42 Z120.0 D01 F250 ; N05…

0 BEGIN PGM 10127 MM 1 BLK FORM 0.1 Z X-50 Y-50 Z-40 2 BLK FORM 0.2 X+50 Y+50 Z+0 3 TOOL DEF 1 4 TOOL CALL 1 Z S1000…

Fanuc G70 G71 Rough and Finish Turning Cycle Program Example

Here is another cnc lathe program example. This cnc programming example shows the use of Fanuc cnc control G-code for turning canned cycle Fanuc G71 Roughing Cycle. This cnc program…

Selca G75 G76 Polar coordinate programming

Selca G75 G76 Polar coordinate programming ContentsG75 Cancels G76ProgrammingG76 Polar coordinate programmingProgrammingParameters G75 Cancels G76 G75 Cartesian coordinate programming (cancels G76) Programming G75 Enabled: (default) until a G76…

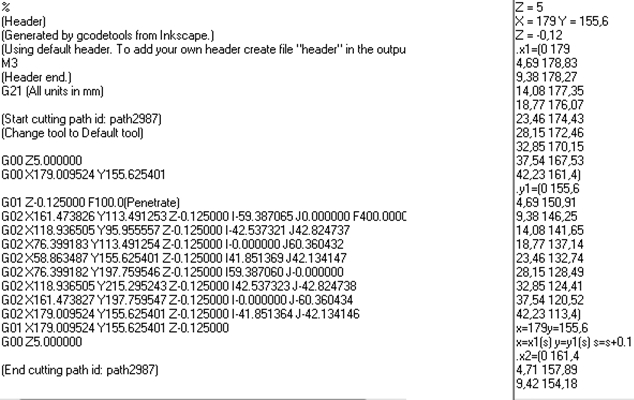

Fanuc CNC Program Example

Here is a cnc program example for Fanuc cnc control. This is a very simple and easy cnc program example also shows Use of G02 Arc/Radius in Fanuc cnc program…

Selca G891 Angles of rotation with inclined probes

Selca G891 Angles of rotation with inclined probes ContentsProgrammingParameters Programming G891 Parameters Parameter Description ROTX… rotation about X-axis. ROTY… rotation about Y-axis. ROTZ… rotation about Z-axis.

Osai 10 Series CNC Program Example

This Osai 10 Series CNC Program Example shows how to use Plane Rotation (ROT) with Repeat (RPT) and Parametric Programming. Osai 10 Series CNC Program Example (UGS, X, -100, 100,…

O777 G91 G28 X0 Y0 Z0 M06 T01 M03 S500 G90 G54 G43 H1 G00 Y41 X0 Z5 G81 Z-12 R2 F200 G16 X41 Y150 X41 Y210 X41 Y270 X41…

G81 Drilling Cycle G84 Tapping Cycle CNC Program Example

CNC program which shows the use of G81 Drilling Cycle G84 Tapping Cycle. As G81 drilling cycle has already been briefly explained here G81 Drilling Canned Cycle – CNC Mill…

Fanuc G21 Measuring in Millimeter with CNC Lathe Programming Example

Fanuc G21 Measuring in Millimeter or Programming in Millimeter. CNC gives us the flexibility to program in metric system or in inches system. Fanuc G21 G-code changes cnc to metric system. So here is another cnc programming example, for beginner level cnc…

Socket with Thread Fanuc 21i CNC Program Exercise

( CONTROL FANUC 21I) ( PART – CYLINDER D102.000 L121.000) ( G54 X+000.000 Z+0240.000) O11 N10 G40 G00 N20 G99 N30 M5 N40 M9 N60 T0101 (LEFT CORNER TOOLCL-SDJCL-2020 L…

Passes

The number of passes that must be cut to make your thread is very important. Take too few passes, and surface finish is apt to be poor and you might even break your threading tool by forcing it to work too hard. Take too many passes and you’re going to waste a lot of time.

You can’t change most of the information relating to the thread’s specifications, so your primary tools for controlling the number of passes include:

– Start Position: Turn things down as I describe above to minimize the work the threading tool must do.

– First Pass Depth: Pick the largest pass you can. G-Wizard Calculator will give you a good recommendation here.

– Minimum Pass Depth: Try to avoid using this parameter too much and set it to your Finish Allowance.

– Finish Allowance: A smaller finish allowance can mean larger roughing passes remove most of the material. Just remember, too small an allowance will force your cutter to rub.

– Spring Passes: You shouldn’t need more than 2 passes and 1 may suffice. Experiment with your particular situation to see if you can get by with 1 or perhaps even no spring passes.

Your next challenge will be in determining how many passes the cycle will actually make. This is not easy as G76 will dynamically change the depth of each pass after the first to equalize the amount of material removed. You have to do quite a lot of calculation to figure out exactly how many passes will be made.

But there if you have a GCode Simulator, it may be able to help out. Take a look at this screen shot of G-Wizard Editor:

G-Wizard Editor will tell you in the hint below the backplot how many passes the G76 cycle will take…

G-Wizard Editor will tell you in the hint below the backplot how many passes the G76 cycle will take. You can use it to help tune your G76 cycle so it doesn’t have an excessive number of passes. Note the WARNING message given that tells you the finish allowance will not be used due to the Minimum Cut Depth being larger. That’s also helpful when setting all this up.

More …

How to Fully Control G76 Threading Cycle Number of Pass and Depth of Cut Explained

Fanuc cnc control is no-doubt the widely used cnc machine control and the most used Fanuc canned cycle is G76 Threading cycle. G76 threading cycle comes with lot and lot…

G78 Threading Cycle – Fanuc Lathe Programming

Fanuc on doubt is the most widely used and understood cnc control. Fanuc is used on variety of machines like mill, lathe etc. So sometimes while dealing with G-codes interesting…

Mach3 Turn G76 Threading Canned Cycle

Mach3 Turn Threading G76 canned cycle is used for threading on a cnc lathe machine which is controlled with Mach3 Turn software. There are other options for threading with Mach3…

Controlling Threading Infeed Angle with Fanuc G76 Threading Cycle

Briefly described how to control thread infeed angle while machining threading on a cnc machine with fanuc cnc control. You better watch the video ( Thread Infeed Tips from Sandvik…

Internal Threading on Fanuc 21i 18i 16i with G76 Threading Cycle

CNC program for the internal threading with G76 threading cycle on fanuc controls 21i/18i/16i. For an example of external threading with G76 threading cycle read External Thread Cutting with G76 Threading…

CNC Fanuc G92 Threading Cycle

This cycle is usually called the G92 threading cycle on Fanuc controls. The Fanuc G92 threading cycle is very simple to program. Fanuc G92 threading cycle does not have any…

G76 Threading Cycle One Line Format for Fanuc 10/11/15T

Fanuc control models 10/11/15 use a one-line format for G76 threading cycle. Other Fanuc control models (0/16/18/20/21) use the double-block format for G76 threading cycle ( G76 Two-line format ). The…

Haas G76 Threading Cycle Multiple Pass

Haas G76 threading cycle can be used for, external threads, Internal threads, straight threads, taper threads. With Haas G76 threading cycle, a programmer can easily command multiple cutting passes along…

Taper Threading with G92 Threading Cycle

Threading is part of almost every component that we machine on a cnc machine. There are multiple G-Codes for threading G32, G33, G76, G92. You can cut tapered threads with…

Fanuc G76 Thread Cycle for Dummies

Fanuc G76 Thread Cycle for Dummies explains Fanuc G76 threading cycle briefly. Fanuc G76 gives cnc machinist full control over thread turning. Fanuc G76 threading cycle has multiple parameters but the same…

Sinumerik L97 Thread Cutting Cycle

Siemens Sinumerik 840C/840 Sinumerik 810/820T cycle L97 Thread Cutting Cycle can be used for External thread cutting Internal threading Taper threading Transversal threads. The tool infeed is automatic and is…

External Thread Cutting with G76 Threading Cycle on Fanuc 21i 18i 16i CNC

ContentsFanuc Series 21i 18i 16i Thread Cutting with G76 Threading CycleCNC Program of External Metric Thread Cutting with G76Related CNC Threading Articles Fanuc Series 21i 18i 16i Thread Cutting with G76 Threading Cycle…

CNC Programming Example G92 Taper Threading Cycle

G92 threading cycle is used for threading on a cnc lathe machine. The added benefit of G92 thread cycle is that G92 G-code gives cnc machinist full control over the…

Taper Threading with G32 a CNC Programming Example

G32 is used for thread cutting, but with G32 we can just make a single threading cut. This all mean that you yourself have to do all the work of…

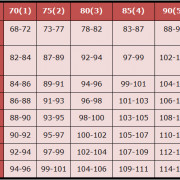

Recommended Thread Infeed Passes Table

Normally it is a practice when a component requires threading we just try to manage the threading cut depth and rarely pay attention to number of thread infeed passes the…

Tapered Threading with Fanuc G76 Threading Cycle

Taper threading is not a usual practice in cnc machine workshops, but sometimes customer want a component with taper threading, So here is the solution. Taper threading on a cnc…

CNC Fanuc G33 G32 Threading G Code

Here is the explanation of cnc G code G33 /G32 which you will see in almost every cnc machine. On Fanuc cnc control this exists as Fanuc G32 G code…

G76 Thread Cycle a CNC Programming Example

G-code G76 is a cnc cycle which is used for thread cutting on cnc machines. Threading cycle G76 is explained here G76 Thread Cycle. Taper thread cutting with G76 thread cycle…

Sinumerik L97 Thread Cutting Cycle Program Example for External Threading

Siemens Sinumerik L97 Thread Cutting Cycle can be used for, external threads, Internal threads, taper threads and transversal threads cutting. Here is a CNC program example which shows how CNC…

More …

How to Fully Control G76 Threading Cycle Number of Pass and Depth of Cut Explained

Fanuc cnc control is no-doubt the widely used cnc machine control and the most used Fanuc canned cycle is G76 Threading cycle. G76 threading cycle comes with lot and lot…

G76 Thread Cycle a CNC Programming Example

G-code G76 is a cnc cycle which is used for thread cutting on cnc machines. Threading cycle G76 is explained here G76 Thread Cycle. Taper thread cutting with G76 thread cycle…

CNC Fanuc G76 Threading Cycle

Threading is an integral part of almost every component which is machined, threads may be internal (ID threading) or external (OD threading). Here is full explanation of G76 Threading Canned…

CNC Fanuc G92 Threading Cycle

This cycle is usually called the G92 threading cycle on Fanuc controls. The Fanuc G92 threading cycle is very simple to program. Fanuc G92 threading cycle does not have any…

G78 Threading Cycle – Fanuc Lathe Programming

Fanuc on doubt is the most widely used and understood cnc control. Fanuc is used on variety of machines like mill, lathe etc. So sometimes while dealing with G-codes interesting…

G76 Threading Cycle One Line Format for Fanuc 10/11/15T

Fanuc control models 10/11/15 use a one-line format for G76 threading cycle. Other Fanuc control models (0/16/18/20/21) use the double-block format for G76 threading cycle ( G76 Two-line format ). The…

Mach3 Turn G76 Threading Canned Cycle

Mach3 Turn Threading G76 canned cycle is used for threading on a cnc lathe machine which is controlled with Mach3 Turn software. There are other options for threading with Mach3…

Taper Threading with G92 Threading Cycle

Threading is part of almost every component that we machine on a cnc machine. There are multiple G-Codes for threading G32, G33, G76, G92. You can cut tapered threads with…

Multi Start Threads with Fanuc G76 Threading Cycle

Fanuc cnc controls has no direct threading cycle for cutting multi start threads on cnc. But you can cut multi start threads on a cnc with fanuc control by using…

Controlling Threading Infeed Angle with Fanuc G76 Threading Cycle

Briefly described how to control thread infeed angle while machining threading on a cnc machine with fanuc cnc control. You better watch the video ( Thread Infeed Tips from Sandvik…

External Thread Cutting with G76 Threading Cycle on Fanuc 21i 18i 16i CNC

ContentsFanuc Series 21i 18i 16i Thread Cutting with G76 Threading CycleCNC Program of External Metric Thread Cutting with G76Related CNC Threading Articles Fanuc Series 21i 18i 16i Thread Cutting with G76 Threading Cycle…

Internal Threading on Fanuc 21i 18i 16i with G76 Threading Cycle

CNC program for the internal threading with G76 threading cycle on fanuc controls 21i/18i/16i. For an example of external threading with G76 threading cycle read External Thread Cutting with G76 Threading…

CNC Programming Example G92 Taper Threading Cycle

G92 threading cycle is used for threading on a cnc lathe machine. The added benefit of G92 thread cycle is that G92 G-code gives cnc machinist full control over the…

Sinumerik L97 Thread Cutting Cycle

Siemens Sinumerik 840C/840 Sinumerik 810/820T cycle L97 Thread Cutting Cycle can be used for External thread cutting Internal threading Taper threading Transversal threads. The tool infeed is automatic and is…

Sinumerik L97 Thread Cutting Cycle Program Example for External Threading

Siemens Sinumerik L97 Thread Cutting Cycle can be used for, external threads, Internal threads, taper threads and transversal threads cutting. Here is a CNC program example which shows how CNC…

Haas G76 Threading Cycle Multiple Pass

Haas G76 threading cycle can be used for, external threads, Internal threads, straight threads, taper threads. With Haas G76 threading cycle, a programmer can easily command multiple cutting passes along…

Siemens Sinumerik 840D Thread Cutting Cycle CYCLE97

With Sinumerik 840D Thread Cutting Cycle CYCLE97 cylindrical and tapered outside and inside threads with constant pitch in longitudinal or face machining can be machined. The thread can be single or multiple. With…

Tapered Threading with Fanuc G76 Threading Cycle

Taper threading is not a usual practice in cnc machine workshops, but sometimes customer want a component with taper threading, So here is the solution. Taper threading on a cnc…

CNC Fanuc G33 G32 Threading G Code

Here is the explanation of cnc G code G33 /G32 which you will see in almost every cnc machine. On Fanuc cnc control this exists as Fanuc G32 G code…

Thread Start and End Positions

The first thing you’ll need to come up with is the thread’s start and end positions. The end position is perhaps a bit easier, particularly in Z, as you generally know exactly the length you want threaded and where that thread starts. The ending diameter is not too bad either as the thread’s specification will tell you that.

Incidentally, our G-Wizard Thread Calculator software has a nice database of common threads that calls out this sort of thing. Here’s a typical screen shot:

G-Wizard Calculator has a database of common threads…

If you don’t have software like G-Wizard Calculator, you’ll have to leaf through your Machinery’s Handbook or something similar to find the information. There are many different thread standards such as the Unified Thread Standard, so make sure you have the correct data for your thread.

The Start Position is a little more interesting. You’ll obviously want to start somewhere outside the threads. You need to leave some allowance in Z to give the CNC lathe time to synchronize the feedrate with the spindle rotational position. It turns out that cutting threads puts more stress on the cutter than a lot of other operations, so you want to turn the OD (External threads) or ID (Internal threads) to get close to the top of the thread to minimize the amount of cutting needed by the threading tool. This will determine the X coordinate you start from. I typically turn down to the top of the thread tooth and use a finish allowance so there’s a nice surface there.

Fanuc G76 Threading Cycle Explanation

N5 G76 P010060 Q100 R0.05 N6 G76 X30 Z-20 P1024 Q200 F2

First block of the G76 Threading cycle

G76 : G code for threading cycle.

P : P actually consists of multiple values which control the thread behavior,

- 01 : Number of spring passes or spring cuts.

- 00 : Thread run out at 45 degree

- 60 : Flank angle or Infeed angle

Q : Depth of normal cut ( these values are given in hundreds, so the depth of cut will be 0.1 ).R : Depth of Last or Finish cut

Second block of the G76 Threading cycle

G76 : G code of the threading cycle.X : The end value in x-axis.Z : The end value in z-axis.P : Thread depth ( as radius value ).Q : Depth of first cut.F : Thread PitchR : Thread Taper

First Cut Depth

This value specifies the depth of the first pass. This should be the deepest cut you make since each subsequent cut will be harder on cutter and machine if you make every subsequent pass as deeply as the first one. The reason is the triangular shape of the thread cutter. As you push the triangle deeper into the cut, more and more area is being cut.

How much material should you try to remove on that first cut?

You can consult the cutter manufacturer, go on your experience, or you could use G-Wizard Calculator’s handy Cut Depth Calculator:

GW Calculator suggest a depth of 0.018″ for the first pass on a 1/4-20 thread…

GW Calculator suggest a depth of 0.018″ for the first pass on a 1/4-20 thread, and it even estimates it will take 6 passes to cut the thread. We’ll talk about the passes in a minute, but suffice to say that unless you actually simulate ALL the parameters of G76, you can only estimate the number of passes that will be needed.

Spring Passes

A Spring Pass is a pass cut at the same depth as the prior pass. It’s called a “Spring Pass” because it is combating the tendency of the part to spring away from the cutting pressure and then spring back afterward without having the full depth of cut taken. Spring passes can help clean up and debur a thread and minimize errors in the thread’s dimensions.

Some versions of the G76 threading cycle have a built-in parameter for spring passes. For example, in the Fanuc double block format, digits 1 and 2 of the P-word specify the number of spring passes to make. In Mach 3, Q specifies spring passes, and in LinuxCNC it is H.

Other controls may specify spring passes with a parameter, or they may not have a way to specify spring passes. When you don’t have a way to specify spring passes, you can use G92 to specify spring passes. Just program one or more G92’s right after the G76 cycle and you’ll retrace the thread contour perfectly.

Typically, two Spring Passes is plenty and one will often suffice, so it’s quick and easy to slap in one or two G92’s after the G76 threading cycle.

Fanuc robodrill

Станки robodrill , широко универсален ,станок применяют для различных расточных и фрезерных операций .Станок предназначен для высокоточных обработок изделий ,отличается максимальной точностью и надежностью обработки .-прямой привод осей ,обеспечивает ускорение в 1,5G по трем осям со скоростью до 54 м/мин.-высокоскоростной шпиндель 10 000-24 000 об/мин.-для сокращения время цикла и качественной обработки имеет контроль оптимального ускорения и торможения.-большой рабочий ход 700*400*330 мм- за счет своей небольшой массы способствует наименьшей затраты на электроэнергию.

Minimum Cutting Depth

Most versions of G76 allow you to specify a minimum cutting depth. This ensures things won’t take too long by running excessively small depth passes. Given that G76 can automatically adjust cut depth on each pass to equalize the amount of material removed, the passes will get smaller, and it takes a fair amount of calculation to figure out how much any given pass will be taking off.

This parameter just makes it easy to get control over that. Be careful not to get too carried away with it though. For most GCode dialects, specifying a Minimum Cut Depth that’s larger than the Finish Allowance may prematurely end the threading cycle without taking the finish pass.

Циклы сверления и формирования отверстий

Для fanucа применяют циклы сверления G81 , для центрования и подрезки G 82 глубоко сверления с выводом после каждого шага величиной К в исходную позицию G 83 , нарезания резьбы метчиком с помощью специального компенсирующего устройства G84 , растачивания , развертывания G85 , растачивания G86 , обработки отверстий с остановкой и ориентацией шпинделя в точках G87 , специального растачивания G89 , сверления с дроблением стружки путем отвода сверла на 1 мм, финишной обработки отверстий G76 4 Токарные циклы Нарезание резьбы с постоянным шагом G32 можно нарезать резьбу с постоянным шагом на конусе и закрученную резьбу. Позиция шпинделя считывается из кодировщика позиции шпинделя в режиме реального времени и конвертируется в значения подачи в режиме подачи в минуту, которая используется для перемещения.Многократно повторяемый цикл G70-G76 имеется несколько типов постоянных циклов, которые облегчают программирование -данные о форме заготовки после чистовой обработке , описывают траекторию движения для черновой обработки .- предусмотрен цикл постоянной нарезания резьбы .Удаления припуска при точении G71 при точении применяю два типа удаления припуска тип 1и 2

Для точения вдоль торца вала используется цикл G72 параметры у него аналогичные меняется направление точения.5 Сообщения об ошибках и их устранение Рассмотрим несколько параметров (сообщений об ошибках)-Отображение и работа 1-Аппаратное обеспечение 91-Ввод и вывод данных 191-Интерфейс между ЧПУ и РМС 308-функция встроенной сети интернет 352-шпиндель АС 390-поиск неисправностей 411-перечень сигналов тревоги 481-загрузочная система 556-слот карты памяти 580-монитор IPL 588-очистка памяти 592Пример: 400 – 401: Сигналы тревоги сервомеханизмаOVL: Перегрузка. Сигнал тревоги 400 Описание в диагностических данных 205.LV: Низкое напряжение. Проверить индикаторы.OVC: Тревога перегрузки по току. Проверить индикаторы.HCA: Тревога ненормального тока Проверить индикаторы.HVA: Тревога ненормального тока Проверить индикаторы.DCA: Тревога платы регенеративной разрядки. Проверить индикаторы.FBA: Тревога отключения

Thread Infeed Angle (also called Tool Nose Angle)

Back in the days of manual lathes, the machinist used to set the compound slide at an angle to the thread that’s called the infeed angle. Being able to set that angle is important to ensuring a constant amount of material is removed and that the cutting spreads the wear to both sides of the insert or cutter.

Illustration by Sandvik shows three infeed strategies…

The illustration above, courtesy of Sandvik, shows thread infeed strategies:

– Radial Infeed: Go straight in with a 0 degree angle. Note that the force increases steadily into the cut as more area is being cutter the deeper we go.

– Modified Flank Infeed: Go in at an angle, which helps spread the wear and keep the force constant.

– Incremental Infeed: Alternate side-to-side while feeding at an angle.

Radial Infeed is quick and dirty, but it produces a stiff V-shaped chip which may have difficulty forming. The insert tip can also reach very high temperatures. This method is suitable for fine pitches, but for coarse pitch threads it often results in too much vibration (chatter) and poor chip control.

The Modified Flank Infeed is the one most commonly programmed in CNC machines. By choosing the right angle, we can avoid having the insert rub. Chips are formed much more easily. The chips are thicker than for a Radial Infeed, but they are much better behaved. As a result, fewer passes are often required and less heat is generated.

When specifying the thread angle, most people use an A58 for a 60 degree thread tool. This will cause the tool to move in at a 29 degree ( 58 / 2 ) angle on each pass thus cutting mostly on one side and just a little on the other side. if you program an A60 the tool will feed in at a 30 degree angle just cutting on one side.

If you’ve got a really large thread to cut, the Incremental Infeed method is probably best. Unfortunately, Incremental Infeed is not available on most G76 threading cycles.